Lube-Shuttle® Canada

AirTec® MoS2 Moly High Pressure Grease Cartridge for Lube-Shuttle®

Couldn't load pickup availability

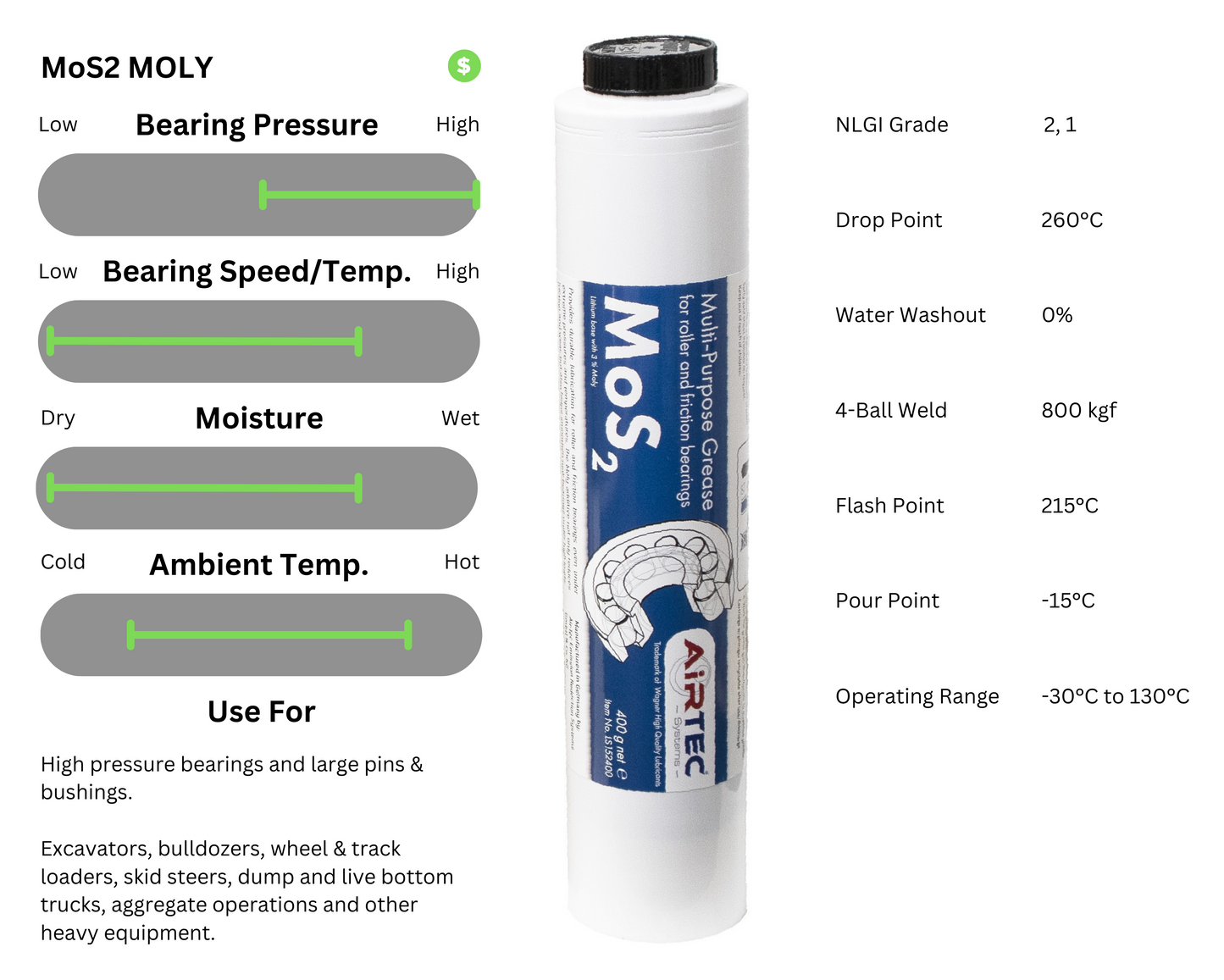

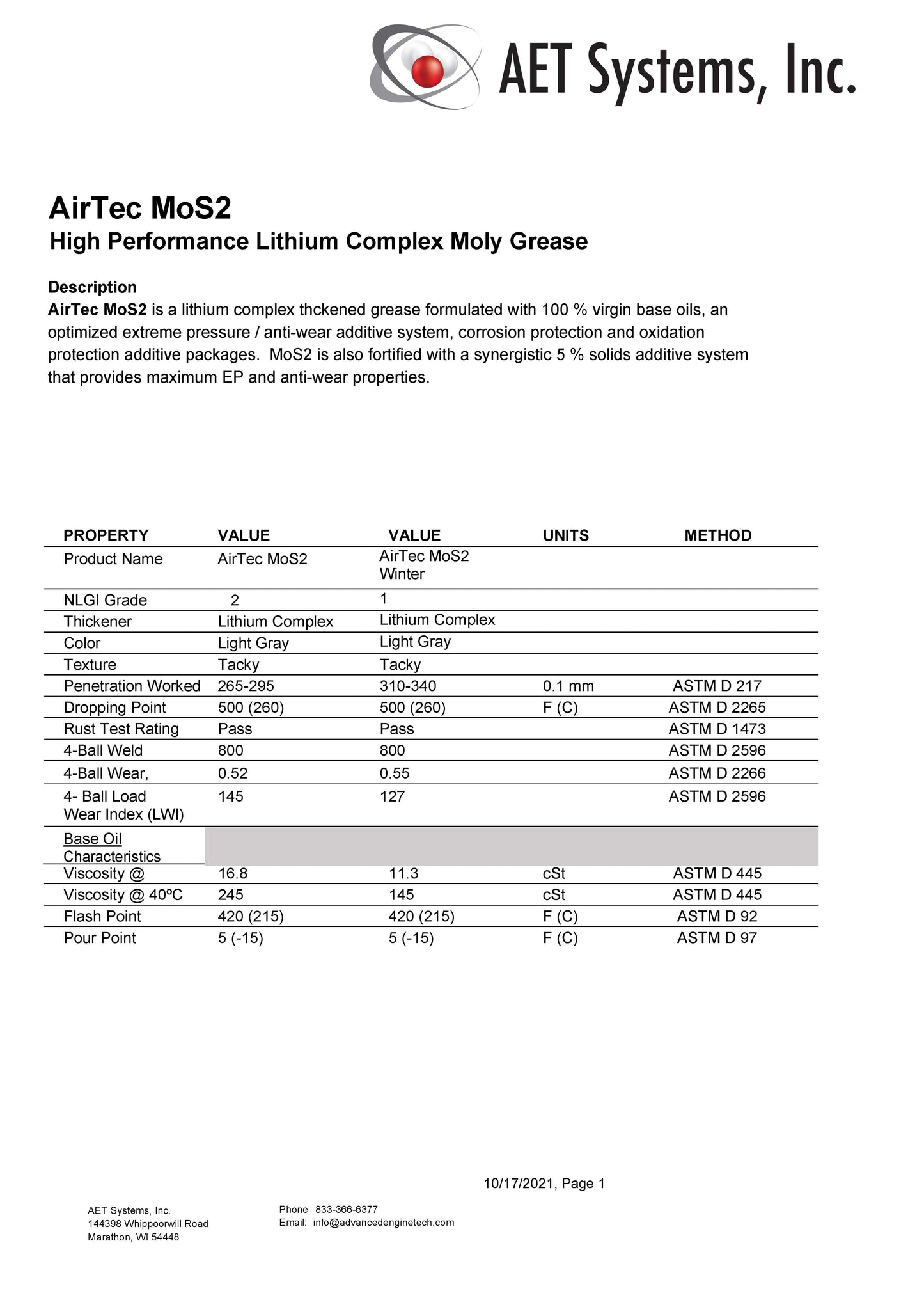

AirTec® MoS2 Moly for Lube-Shuttle® is a premium general purpose grease containing 3% molybdenum disulfide for lubricating points exposed to high pressure loads. It features a lithium complex, corrosion inhibitors, polymers for better metal adhesion, and anti-oxidant additives. It has a heavier base oil than most mass-market Moly greases.

This grease is best used in high-stress wheel and friction bearings found in suspensions, heavy construction equipment, and industrial machines. It's a great all-round grease for a wide temperature range and for high-pressure situations. This product meets standards where Moly grease is specified by equipment manufacturers.

- Base Oil Vis. (40°C) 245 cSt

- Temperature Range -30°C to +120°C

- Drop Temperature 260°C

- 4-Ball Weld Load 800 kgF

- Specifications DIN 51502 KPF 2 K-30 NLGI 2 (1 also available)

MoS2 grease, also known as molybdenum disulfide grease or moly grease, is a type of lubricant that contains molybdenum disulfide particles suspended in a grease base. MoS2 grease offers specific benefits and is commonly used in various applications due to its unique properties. Here are some of the typical uses and advantages of MoS2 grease:

-

High-Load Applications: MoS2 grease is well-suited for high-load applications where extreme pressure and heavy loads are present. The molybdenum disulfide particles in the grease form a solid lubricating film that can withstand significant pressure and reduce friction between metal surfaces.

-

Boundary Lubrication: MoS2 grease excels in boundary lubrication conditions, where the lubricant film can be easily squeezed out due to high pressure or low speeds. The solid lubricating film formed by molybdenum disulfide particles acts as a protective barrier, preventing direct metal-to-metal contact and reducing wear.

-

Extreme Temperatures: MoS2 grease performs well in both high and low-temperature environments. It can withstand high temperatures without losing its lubricating properties or degrading. Additionally, MoS2 grease retains its effectiveness in low-temperature conditions where other lubricants may become less efficient or solidify.

-

Anti-Seizing and Anti-Galling: MoS2 grease is commonly used for applications where the prevention of seizing or galling is crucial. The molybdenum disulfide particles provide a barrier between contacting surfaces, reducing the likelihood of friction-induced damage and metal-to-metal welding.

-

Slow-Speed and Oscillating Movements: MoS2 grease is effective for slow-speed or oscillating movements, where boundary lubrication conditions may occur. The solid lubricant film created by the molybdenum disulfide particles helps maintain lubrication and reduce wear in such applications.

-

High-Pressure Environments: MoS2 grease is frequently used in high-pressure environments, such as in heavy machinery, mining equipment, industrial gearboxes, and automotive applications. Its ability to withstand extreme pressure and reduce friction makes it suitable for such demanding conditions.

It is important to note that while MoS2 grease has unique advantages in certain applications, it may not be suitable for all lubrication needs. Factors such as operating conditions, equipment requirements, and manufacturer recommendations should be considered when selecting the appropriate lubricant for a specific application.

We have variants of MoS2 that are suitable for live-bottom aggregate haulers, specialized mining equipment, winter use, and various other applications. Contact us to inquire.